Description

Application:

Suitable for preformed bag powder packing , such as milk powder, glucose, monosodium glutamate, seasoning, washing powder, chemical materials, fine white sugar, pesticide, fertilizer, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. Wide range of pouches: all kinds of pre-made pouches such as flat and stand-up pouches (with/without zip).

2. Easy To Operate:PLC control, man-machine interface is friendly.

3. Variable frequency speed regulation:Used frequency conversion adjustment device, the speed can be adjusted within the range according to the needs of reality in production.

4. Easy to adjust the clip width:Control by motor;Only by a button you can sync control 8 sets of clip.

5. The material level is all made of stainless steel 304 or food-degree plastic according with food hygienic requirement.

6. Use no oil vacuum pimp,avoid polluting the enviroment in the production.

7. Easy to clean:the machine table can be washed.

Parameter

| Model | VK-8200/VK-8250 |

| Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

| size | W:70-200/100-250 |

| Filling range | 10-1000g/20-2500g |

| Packing speed | 40-60bag/min(speed is determined by the product filling quantity) |

| Average precision | ≤ ±1% |

| Total power | 2.5KW |

| Dimensions | 1900mm X 1570mm X 1700mm(L*W*H) |

| Work flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

| Main standard parts | 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

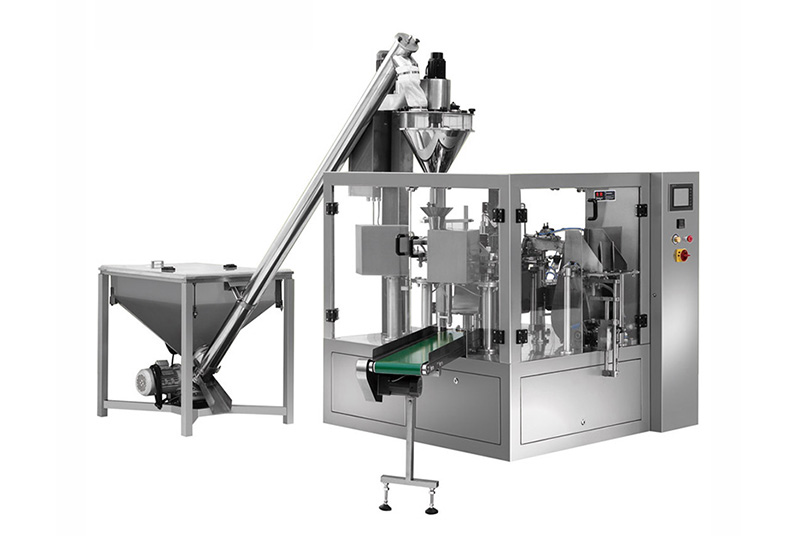

A powder premade pouch rotary doypack machine is a type of packaging machine used in the manufacturing industry to fill and seal premade pouches with powdered products. The machine is designed to handle a wide range of premade pouch sizes and shapes, making it suitable for different production needs.

The operation of the powder premade pouch rotary doypack machine is simple and straightforward. The premade pouches are placed onto the machine's conveyor belt, and the machine uses a rotary filling system to accurately fill each pouch with the required amount of powder. The machine is designed to be fast and efficient, capable of filling and sealing hundreds of pouches per minute.

One of the advantages of using a powder premade pouch rotary doypack machine is its high level of accuracy and speed. The machine is designed to accurately measure and dispense the predetermined amount of powder into each premade pouch, ensuring that each pouch is filled to the correct level. This helps to maintain the quality and consistency of the product, reducing the risk of overfilling or underfilling each pouch.

In addition to improving accuracy and speed, the powder premade pouch rotary doypack machine also helps to reduce labor costs and increase productivity. The machine is designed to be easy to operate and maintain, which means that manufacturers can spend less time on filling and more time on production.

The sealing process of the machine ensures that the premade pouches are tightly sealed, preventing any contamination of the powdered product. This also helps to prolong the shelf life of the product, ensuring that it remains fresh and of high quality for a longer period.

In conclusion, the powder premade pouch rotary doypack machine is an essential piece of equipment for powdered product manufacturers. It provides an accurate and efficient way to fill and seal premade pouches with powder, ensuring that each pouch is filled to the correct level and maintaining the quality and consistency of the product. The machine is fast, versatile, and customizable, making it a valuable investment for manufacturers looking to improve the efficiency and productivity of their production processes.