Description

Application:

Suitable for packing powder materials such as coffee powder, medicinal powder, milk powder, juice powder, chocolate powder, grain powder, green tea powder, healthy powder etc in the industries of phamacy, food and agricultural chemicals.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

English and Chinese screen display, operation is sample.

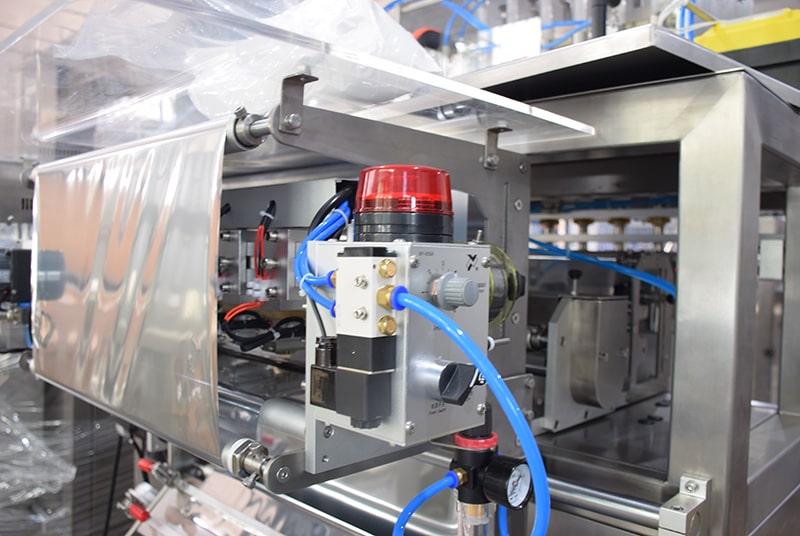

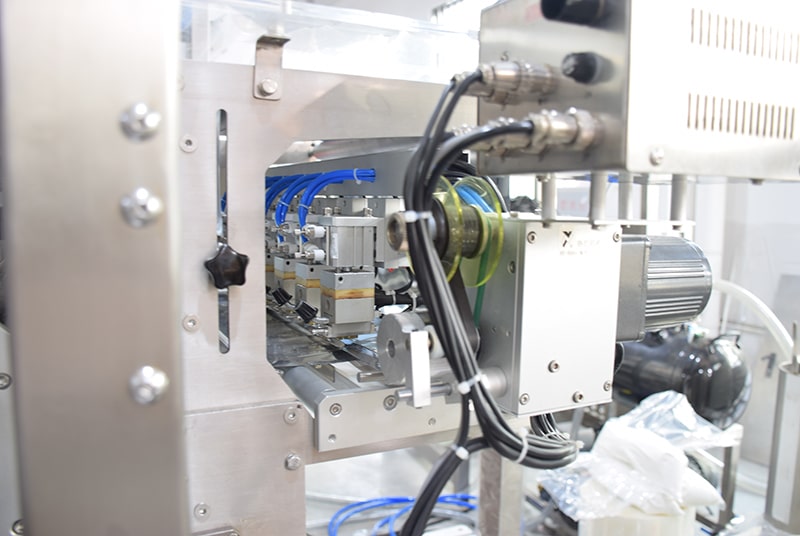

PLC computer system, function is more stable, adjustment any parameters not need stop machine.

It can stock ten groups of parameters, simple to change variety.

Servo motor drawing film, positing accurately.

Temperature independent control system, precision get to 1 degree.

Horizontal, vertical temperature control, suitable for various of mix film, PE film bag material etc.

Parameter

| Filling product | Powder |

| Filling volume | 1-40ml |

| Lane | 5 lanes |

| Max.packing width | 320mm |

| Width of bag | 15-40mm |

| Bag length range | 35-200 |

| Packing material core diameter | Φ70—Φ76mm |

| Total power (Kw) | 8kW |

| Filling accuracy | ±5% |

| Power supply | 380V 50Hz |

| Compressed air consumption | 0.25m3/h |

| applicable film | CPP/PE/OPP,CPP/PT,PE/KOP,CPP,PET/AL/PE,PET/PE,NY/AL/PE,NY/PE |

| Max.width of packing material(roll film) | 380mm |

| Max.outer diameter of packing material(roll film) | Φ300mm |

| Max.cutting frequency | Max.35bags/min/lane X 5lanes,it is depended on size of actual bags. |

| Max.capacity | Max.140bags/min |

| dimension(L*W*Hmm) | 1.1mX1.2mX2.2m |

| Weight | 1350kg |

The multi-line sugar sachet packing machine is a sophisticated piece of equipment that has revolutionized the sugar packaging industry. With its cutting-edge technology and precision engineering, this machine is capable of producing a large number of sugar sachets in a short period of time, making it an ideal choice for manufacturers and distributors who need to meet high-volume production requirements.

The multi-line sugar sachet packing machine is designed to package granulated sugar into small, single-use sachets, which are commonly used in restaurants, hotels, and other food service establishments. The machine is capable of packing sugar in various sizes, ranging from 5g to 20g, and can pack multiple sachets simultaneously, with up to four lines of sachets being produced simultaneously.

The machine operates by first dispensing the sugar from a bulk supply hopper into individual sachets, which are then sealed and cut to size. The sealing process is accomplished through the use of heat-sealing technology, which ensures that the sachets are properly sealed and will not leak or tear during transport.

One of the key benefits of the multi-line sugar sachet packing machine is its high level of automation, which reduces the need for manual labor and increases production efficiency. The machine is equipped with advanced sensors and controls, which monitor the packing process and make adjustments as needed to ensure that each sachet is filled with the correct amount of sugar.

Overall, the multi-line sugar sachet packing machine is a reliable and efficient piece of equipment that can greatly improve the productivity and profitability of any sugar packaging operation. With its advanced technology and precision engineering, this machine is a valuable asset for any manufacturer or distributor looking to streamline their sugar packaging process and increase their bottom line.