Description

Application:

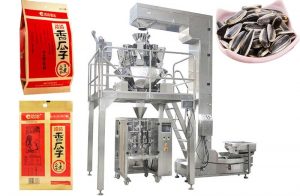

Vertical Full automatic volumetric cup filler metering packaging machine, apply to pack bulk grain, slice, short bar material products such as puffy food, popcorn, shrimp chip, salt, sugar, rice, sunflower seed, peanut, beans, nuts, pistachio, peas, instant oatmeal / cereal oats, etc.

Kindly Reminde

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

It completes the whole procedure of feeding, metering, bagging, date printing charging(exhausting), product out-putting automatically.

A com plete set of equipment is economical.

The volumetric cups can be make to open-close model measure equipment.

Parameter

| Model | VK-420C | VK-520C | VK-720C |

| Film Width | Max.420mm | Max.520mm | Max.720mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm |

| Roll Diameter | Max.320mm | Max.320mm | Max.320mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Measuring Range | 150-1500ml | 2000ml | 4000ml |

| Packing Speed | 5-60bag/min | 5-60bag/min | 5-55bag/min |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW | 220V 50/60Hz 3KW |

| Machine Size(L*W*H) | 1217*1015*1343mm | 1488*1080*1490mm | 1780*1350*2050mm |

| Machine Weight | About 650kg | About 680kg | About 750kg |

| Option Device | 1.Date Printing, 2. Hole Punching Device(Pinhole, Round hole, the butterfly hole), 3. Air-filling Device, 4. Tear Notch Device | ||

The automatic popcorn pouch packing machine with volumetric cup is an innovative solution for businesses looking to streamline their production processes. This machine offers a variety of benefits, including improved efficiency, reduced labor costs, and increased product quality. With its volumetric cup technology, the machine is able to accurately measure and fill pouches of any size with the exact amount of popcorn needed. Additionally, this machine is designed to be user-friendly and easy to maintain, making it an ideal choice for businesses that need a reliable packaging solution. By exploring the benefits of this cutting-edge technology, businesses can ensure that their production process runs smoothly and efficiently while delivering high-quality products to their customers.

Overview of the Automatic Popcorn Pouch Packing Machine with Volumetric Cup

The Automatic Popcorn Pouch Packing Machine with Volumetric Cup is a highly efficient and reliable packing machine designed for the automated packaging of popcorn. It features a volumetric cup that accurately measures out the desired amount of popcorn, ensuring consistent quality and weight. The machine also features an adjustable speed control system to adjust the flow rate according to product requirements. The pouch packing system can be customized with various types of bags, including stand-up pouches, pillow pouches, and gusseted pouches. Additionally, it is equipped with a bag opening device that ensures proper filling of the pouch and minimizes product waste. This machine is ideal for large-scale production operations in snack food manufacturing facilities.

Benefits of Automation in Popcorn Packaging

Automation in popcorn packaging offers a number of benefits to businesses. Automated systems are more efficient and cost-effective than manual packaging, as they require fewer personnel and resources. Automation also increases accuracy, consistency, and speed of production, resulting in improved product quality and reduced waste. Automated systems are also able to handle a wide variety of products with different sizes, shapes, and textures without the need for manual intervention. Additionally, automated systems can be easily integrated into existing production lines for increased efficiency. Finally, automation reduces the risk of injury or illness associated with manual packaging processes by eliminating repetitive motions or tasks that can lead to musculoskeletal disorders.

Advantages of Volumetric Cup Technology for Accurate Filling

Volumetric cup technology is a highly accurate and reliable method of filling products into containers. This technology uses volumetric cups, which are specially designed cups that accurately measure the volume of product being filled. The volumetric cup technology is ideal for products that require precise filling, such as food and beverage items. It is also used in the pharmaceutical industry for accurate dosing of medications.

The advantages of using volumetric cup technology for accurate filling include: accuracy, repeatability, speed, and cost-effectiveness. Volumetric cups are designed to ensure accuracy in the amount of product being filled into each container; this eliminates any guesswork or manual measuring when filling products. Additionally, this technology ensures repeatability in terms of consistency between each fill; this means that each container will be filled with the same exact amount every time it is filled with a product. Furthermore, volumetric cup technology can fill containers quickly due to its automated nature; this helps increase production efficiency and reduce labor costs associated with manual filling processes. Finally, using volumetric cups can help save money on packaging materials since they only use what is necessary to accurately fill each container without any excess material waste.

Overall, volumetric cup technology provides an efficient and cost-effective way to accurately fill products into containers while maintaining high levels of accuracy and consistency between each fill.

Cost Savings Achieved by Using an Automatic Pouch Packing Machine

The use of an automatic pouch packing machine is a cost-effective solution for businesses looking to increase their efficiency and reduce their costs. This type of machine can be used to package products quickly and accurately, eliminating the need for manual labor and saving time and money. The machine is capable of sealing pouches with a variety of materials, including paper, plastic, foil, and more. It also features adjustable settings that allow users to customize the speed and quality of the packaging process. Additionally, it can be programmed to accommodate different product sizes or shapes for increased flexibility. By using an automatic pouch packing machine, businesses can save money on labor costs while ensuring that their products are properly packaged in a timely manner.

Quality Assurance and Improved Efficiency with Automated Packaging Solutions

Automated packaging solutions are an essential part of any quality assurance program. By automating the packaging process, companies can reduce costs and improve efficiency while ensuring that their products meet the highest standards of quality. Automated packaging solutions use advanced technologies such as robotics, vision systems, and software to streamline the packaging process. This helps to reduce errors and improve accuracy in product labeling, packing, sealing, and other tasks. Automation also helps to reduce labor costs by eliminating manual processes that are time-consuming and prone to human error. In addition, automated solutions can help companies achieve greater consistency in their products by ensuring that all products are packaged with uniformity and accuracy. Automated packaging solutions also provide improved traceability of goods throughout the supply chain which is essential for quality assurance purposes.

Conclusion

The Automatic Popcorn Pouch Packing Machine with Volumetric Cup in a size is an excellent choice for businesses looking to increase efficiency and reduce costs. This machine offers a wide range of benefits, including increased accuracy, improved speed, and decreased labor costs. Additionally, the volumetric cup ensures that each pouch is filled to the exact desired size. By utilizing this machine, businesses can save time and money while still producing high-quality products.