Description

Application:

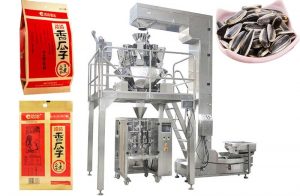

All kinds of grains and solids material, like candy, nuts, raisins, peanuts, melon seeds, nuts,nutlet, chocolate, preserved fruit,potato chips,biscuits,confect, camphorball, currant, almond,potato crisps, pet food, dilatant food etc can be weighed by the ration. It is also suitable for weighing small hardware and plastic component.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. wide applications: various state and nature of solid(granule);

2. A wide range of pouches: all kinds of pre-made pouches;

3. Easy to operate: PLC controller, HMI system makes easy operation;

4. Easy to adjust: change different pouches within 10 minutes;

5. High automation: unmanned in weighing and packing process, machine alarm automatically when failure;

6. Perfect prevention system: when the bag is not opened or not opened completely, it will be non-filling and non-sealing, so the bags can be reused and the product is not wasted thus save the production cost;

7. The product contact parts are adopted SUS304 to ensure sanitation and safety, meet the GMP standard;

8. Imported engineer plastic bearings, no need to oil, no contamination;

9. Vacuum generator: low consumption, high efficiency, cleaness, and long useful life;

10. Pre-made bag packing: perfect sealing quality, upgrade the finished product.

Parameter

| Model | VK-8200/VK-8250 |

| Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

| size | W:70-200/100-250 |

| Filling range | 10-1000g/20-2500g |

| Packing speed | 40-60bag/min(speed is determined by the product filling quantity) |

| Average precision | ≤ ±1% |

| Total power | 2.5KW |

| Dimensions | 1900mm X 1570mm X 1700mm(L*W*H) |

| Work flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

| Main standard parts | 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

A Nuts Rotary Packing Machine for Premade Pouch / Zipper Pouch in a size is the perfect solution for businesses looking to maximize their efficiency. This advanced machine offers an efficient and cost-effective way to package a variety of products, including nuts, dried fruits, and other food items. It is capable of packing up to 400 pouches per minute with minimal labor costs. The machine also features adjustable settings that allow you to customize the size of each pouch, ensuring that your product is always packed securely and accurately. With its robust design and high-quality components, this machine is sure to provide reliable performance for years to come.

Maximizing Output with a Nuts Rotary Packing Machine

A Nuts Rotary Packing Machine is an automated packing solution designed to maximize output for a variety of nut-based products. This machine is capable of packaging up to 10,000 nuts per hour and can be easily integrated into existing production lines. The machine is equipped with a rotary filling system that allows for quick and accurate filling of bags or containers with the desired product. The adjustable settings on the machine allow for precise control over the amount of product being packed, ensuring consistent results. Additionally, the machine is designed to minimize waste and maximize efficiency by using a vacuum system to eliminate air pockets in the packaging. This ensures that all product is packed securely and safely while reducing material costs. The Nuts Rotary Packing Machine is an ideal solution for businesses looking to increase their output while maintaining quality standards.

Utilizing Automation for Increased Efficiency

Automation is an increasingly popular tool for increasing efficiency in many industries. Automation allows businesses to automate repetitive tasks, freeing up time and resources for more important tasks. Automation can also reduce the amount of human error in processes, resulting in higher quality output. Automation can also be used to streamline processes, reducing the amount of time needed to complete a task and increasing productivity. Additionally, automation can help reduce costs associated with manual labor, as it eliminates the need for additional personnel or training. Automation is a powerful tool that can be used to increase efficiency and improve overall performance in any industry.

Streamlining Premade Pouch and Zipper Pouch Production

Streamlining premade pouch and zipper pouch production is a process that involves optimizing the production process to reduce costs and increase efficiency. It typically involves utilizing modern technology and automation to reduce labor costs, streamline production processes, and increase throughput. By utilizing automated machinery, such as pouch-making machines, premade pouch and zipper pouch production can be made more efficient by reducing the number of steps required to produce the product. Additionally, automated machinery can also help reduce waste materials and improve product quality. Automation also helps reduce labor costs by allowing for fewer workers to be employed in the production process. Furthermore, streamlining premade pouch and zipper pouch production can help improve product consistency by reducing variability in the finished product. By streamlining premade pouch and zipper pouch production, companies can save time, money, and resources while producing high-quality products with greater efficiency.

Exploring Advanced Features of a Nuts Rotary Packing Machine

The Nuts Rotary Packing Machine is a high-performance automated packing solution designed to meet the needs of industrial production lines. This advanced machine offers a range of features that make it an ideal choice for packing nuts and other small items. It is capable of automatically sorting, counting, and packing items into bags or boxes with great accuracy and speed. The machine can also be customized to meet specific production requirements.

The Nuts Rotary Packing Machine is equipped with a wide range of advanced features that make it highly efficient and reliable. It features a fully automatic weighing system that ensures accurate weight measurements for each item being packed. The machine also has an adjustable speed control system which allows users to adjust the speed according to their production needs. Additionally, the machine is equipped with a number of safety features such as an emergency stop button and overload protection system which ensure the safety of operators and equipment during operation.

The Nuts Rotary Packing Machine also offers several other advanced features such as automatic product detection, multiple packing formats, and remote monitoring capabilities. These features allow users to monitor the performance of the machine in real-time from any location, ensuring maximum efficiency and reliability during operation. Furthermore, this advanced machine can be easily integrated into existing production lines for seamless operation.

Overall, the Nuts Rotary Packing Machine is an ideal choice for industrial applications due to its wide range of advanced features that make it highly efficient and reliable in operation.

Optimizing Operational Costs with a Nuts Rotary Packing Machine

A Nuts Rotary Packing Machine is an efficient and cost-effective way to package a variety of nuts. This machine utilizes a rotary filling system that is designed to optimize operational costs by reducing labor, material, and energy costs. The rotary filling system ensures that each nut is accurately and quickly filled into the packaging material, eliminating the need for manual labor. The machine also features adjustable settings that allow for precise control over the speed of production, ensuring consistent results. Additionally, the machine is equipped with a high-efficiency motor that reduces energy consumption while providing reliable performance. With its robust design and easy-to-use controls, the Nuts Rotary Packing Machine is an ideal solution for businesses looking to optimize their operational costs.

Understanding Maintenance Requirements for a Nuts Rotary Packing Machine

Understanding the maintenance requirements for a nuts rotary packing machine is essential for ensuring its safe and efficient operation. This type of machine is used to package nuts into bags or containers at high speeds, and requires regular maintenance to keep it running smoothly.

Maintenance should begin with a visual inspection of the machine, checking for any signs of wear or damage. The moving parts should be lubricated according to the manufacturer’s instructions, and all belts and pulleys should be checked for proper tension. Any worn or damaged parts should be replaced immediately.

The machine should also be cleaned regularly, using a vacuum cleaner or compressed air to remove any dust or debris that may have accumulated in the internal components. The conveyor belt should also be inspected for any signs of wear or damage, and replaced if necessary.

Finally, it is important to check the settings on the machine regularly to ensure that they are correct and that the nuts are being packaged correctly. Any adjustments that need to be made should be done carefully, following the manufacturer’s instructions.

By following these maintenance requirements, operators can ensure that their nuts rotary packing machine runs safely and efficiently at all times.

Conclusion

The Nuts Rotary Packing Machine for Premade Pouch / Zipper Pouch is an efficient and reliable solution for businesses looking to maximize their production efficiency. With its robust design, high-speed operation, and precise bag size control, this machine can quickly and accurately package products of any size. Additionally, its user-friendly interface makes it easy to operate and maintain. By utilizing the Nuts Rotary Packing Machine for Premade Pouch / Zipper Pouch, businesses can increase their production output while reducing costs associated with manual labor.