Description

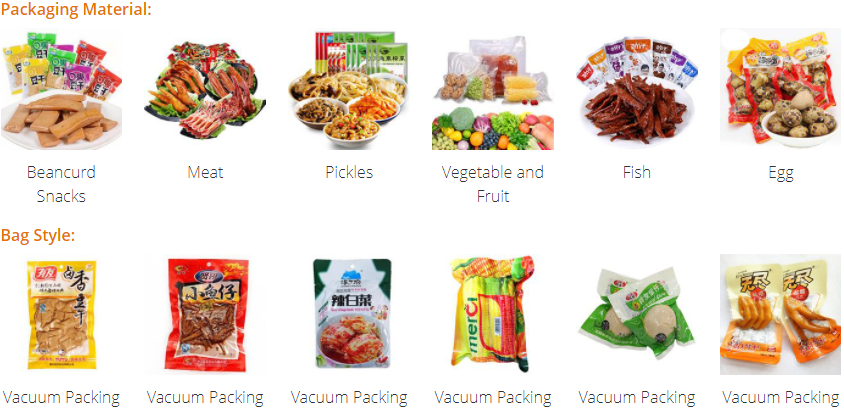

Application:

Suitable for packaging soybean products, meat products, egg products, pickles and other foods that require vacuum packaging.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Filling system vacuum system;

Automatically adjust the bag width;

Can pack different products;

Contact material 304 stainless steel;

Siemens and POD control system;

Less pouch waste;

Automatic alarm function;

Instant heating and water cooling, more beautiful bag shape;

Vacuum chamber = aviation aluminum;

Ensure tightness and durability of the pouch.

Parameter

Pouch Type: Four-side seal bags, stand-up pouches , zipper bags, three-side seal bags, paper bags, etc.

Bags Size: W:60-120 mm L: 55-130mm

Filling Volume:15-200g

Capacity: 40-60 bags/min

Dimension: 2100×1400×1700(L*W*H)

weight: 1600KG

compress air requirement: ≥0.6m³/min supply by user

Optional configuration:

1. material weighing Milling machines

2. platform

3. check weigher

4. material elevator

5. finished product conveyor

6. metal detecto

7. Inkjet printer

Investing in quality is essential for businesses that want to remain competitive in the food packaging industry. High quality rotary vacuum food packaging machines offer numerous advantages, such as improved efficiency, enhanced safety, and increased product shelf life. These machines are designed to ensure that food products are safely and securely packaged, while also preserving their freshness and taste. By investing in a high quality rotary vacuum food packaging machine, businesses can benefit from increased productivity, reduced waste, and improved customer satisfaction. Furthermore, these machines can help to reduce costs associated with product spoilage and spoilage-related losses. Investing in a quality rotary vacuum food packaging machine is an investment that will pay off for years to come.

Exploring the Benefits of Investing in High Quality Rotary Vacuum Food Packaging Machines

Investing in high quality rotary vacuum food packaging machines is a great way to ensure that your food products are properly packaged and stored. These machines offer a variety of benefits, including increased shelf life, improved product safety, and cost savings. The vacuum packaging process seals food products in an airtight environment, preventing spoilage and contamination. This helps to extend the shelf life of the product and ensures that it remains safe for consumption. Additionally, the vacuum process to reduce the amount packaging materials needed for each product, resulting in cost savings for businesses. Rotary vacuum food packaging machines are an excellent investment for any business looking to improve their food storage and packaging capabilities.

Understanding the Superior Performance of Quality Rotary Vacuum Food Packaging Machines

Rotary vacuum food packaging machines are an essential tool for the food industry, providing superior performance and quality. These machines are designed to package food products quickly and efficiently, ensuring that they remain fresh and safe for consumption. They feature a rotary vacuum chamber which is used to remove air from the packaging material, creating a vacuum-sealed environment that prevents oxygen from entering the package. This helps to preserve the quality of the food product while also extending its shelf life. The machine also features an adjustable temperature control system which allows for precise temperature control during the packaging process. Additionally, these machines are designed with a variety of safety features such as automatic shut-off mechanisms and sensors to detect any problems with the machine's operation. With their superior performance and quality, rotary vacuum food packaging machines are an invaluable asset to any food production facility.

Analyzing the Cost-Savings of Investing in High Quality Rotary Vacuum Food Packaging Machines

Investing in high quality rotary vacuum food packaging machines can provide significant cost savings for businesses. These machines are designed to quickly and efficiently package food products in a vacuum-sealed environment, which helps to extend the shelf life of the product and reduce spoilage. The machines are also designed to be energy efficient, which can help reduce operational costs. Additionally, these machines can help increase production speed and accuracy, leading to greater efficiency and cost savings. By analyzing the cost-savings associated with investing in high quality rotary vacuum food packaging machines, businesses can make informed decisions about their investments and maximize their return on investment.

Examining the Durability and Reliability of Quality Rotary Vacuum Food Packaging Machines

Rotary vacuum food packaging machines are an essential part of the food processing industry. They are used to package a variety of products, from frozen foods to dry goods. These machines are designed to be durable and reliable, providing long-term performance and quality assurance. They feature a variety of features that ensure their reliability and durability, such as high-quality materials, robust construction, and advanced technology. Additionally, they are designed to be easy to use and maintain, making them an ideal choice for any food processing operation. With proper maintenance and care, these machines can provide years of reliable service and excellent results.

Evaluating the Efficiency and Productivity of High Quality Rotary Vacuum Food Packaging Machines

Rotary vacuum food packaging machines are highly efficient and productive machines designed to quickly and effectively package food products. These machines use a combination of vacuum sealing and heat sealing to ensure that food products remain fresh and uncontaminated. They can be used to package a wide variety of food items, including dry goods, liquids, and even frozen items. In order to evaluate the efficiency and productivity of these machines, several factors must be taken into consideration. These include the speed of operation, the accuracy of the seals, the ability to maintain consistent temperatures throughout the packaging process, and the overall quality of the finished product. By assessing these factors, it is possible to determine whether or not a particular machine is suitable for use in a particular application.

Conclusion

Investing in quality rotary vacuum food packaging machines can be a great decision for businesses looking to maximize efficiency and reduce costs. High quality machines are designed to last longer, require less maintenance, and produce consistent results. Additionally, these machines offer the advantage of increased safety for food products as they are able to seal in freshness and prevent contamination. With all these advantages, businesses can be sure that investing in quality rotary vacuum food packaging machines will pay off in the long run.