Description

Suitable:

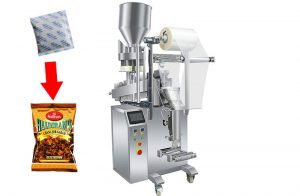

Suitable for mixed product such as hotpot seasoning, mix snacks, mix beans, seasoning, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examples:

1. Products dosing, Filling, Laminate heat sealable pouch making and sealing.

2. Stainless steel 304 structure and surface.

3. Weighing and Packaging PLC & HMI Control Integrated, More stable operation, Easy for parameter setting.

4. Simple changing of pouch former, to adapt different pouch size requirement.

5. Intelligent temperature controlling configuration, ensure the artistic and neat sealing.

6. Configure with packaging film pre-pulling device, to enable stable pouch making

7. Easy to change the packaging film

8. Multi-head combined weigher, improve metering speed and accuracy.

Parameter

| Model | VK-320 | VK-380 |

| Film width | 120-320mm | 180-380mm |

| Bag length | 50-200mm | 60-280mm |

| Bag width | 50-150mm | 60-180mm |

| Diameter of film roll | Max.300mm | Max.320mm |

| Packing speed | 35-70bag/min | |

| Measuring range | 50-500ml | 50-750ml |

| Film thickness | 0.04-0.07mm | |

| Power | 220V 50/60Hz 2.2KW | 220V 50/60Hz 2.5KW |

| Machine size(L*W*H) | 970*680*1950mm | 1100*800*2150mm |

| Machine weight | About 300kg | About 450kg |

If you're in the business of selling granular products such as coffee, sugar, salt, spices, or seeds, you know how important it is to have an efficient and accurate packing process. An automatic low-cost granule weighing packing machine can help you streamline your operations while reducing costs and improving product quality.

Here are some frequently asked questions about this type of machine:

- What is an automatic low-cost granule weighing packing machine?

A: An automatic low-cost granule weighing packing machine is a piece of equipment designed to weigh and pack granular products such as coffee, sugar, salt, spices, and seeds. It can automatically fill and seal bags of various sizes and materials, reducing the need for manual labor and increasing the efficiency of the packing process.

- How does the machine work?

A: The machine works by first filling a hopper with the granular product. The product is then dispensed into a weighing unit that uses load cells to accurately measure the weight of the product. Once the desired weight is reached, the weighing unit sends a signal to the packing unit, which fills and seals the bag. The machine can be programmed to pack bags of various sizes and materials, depending on the needs of the business.

- What are the advantages of using an automatic low-cost granule weighing packing machine?

A: There are several advantages of using an automatic low-cost granule weighing packing machine, including:

- Increased efficiency: The machine can pack bags much faster than manual labor, reducing the time and resources required to pack products.

- Improved accuracy: The machine uses load cells to accurately measure the weight of the product, reducing the risk of under or over-packing bags.

- Cost savings: By reducing the need for manual labor, the machine can help businesses save on labor costs and increase productivity.

- Improved product quality: The machine can pack products in a consistent and uniform manner, improving the overall quality and appearance of the product.

- Is the machine suitable for small businesses?

A: Yes, there are automatic low-cost granule weighing packing machines available that are suitable for small businesses with lower production needs. These machines are typically smaller in size and capacity but still offer the same level of efficiency and accuracy as larger machines.

- What types of bags can the machine pack?

A: The machine can pack bags of various sizes and materials, including paper, plastic, and woven bags. The size and material of the bag can be customized based on the needs of the business.

In conclusion, an automatic low-cost granule weighing packing machine can be a valuable investment for businesses that require efficient and accurate packing processes for granular products. It offers several advantages over manual labor, including increased efficiency, improved accuracy, cost savings, and improved product quality. With various sizes and bag materials available, businesses of all sizes can benefit from using this type of machine.