Description

Application:

Suitable for the filling of various liquids, pastes and sauces, such as alcohol, disinfectant, disposable hand sanitizer, honey, chili sauce, tomato sauce, pearl milk tea, orange juice, etc., with strong versatility.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Piston filling machine, self-priming filling, the material is driven by a single cylinder to drive a single piston to extract the material into the metering cylinder, and then the piston is pneumatically pushed into the container through the material tube. High installation accuracy, easy to use and flexible;

Equipped with no bottle and no filling function, the liquid level automatically controls feeding, effectively reducing equipment failure;

Program control adopts PLC touch screen manual operation interface to realize intelligent control;

To adjust the filling volume, each piston cylinder must be adjusted one by one;

The filling nozzle is made of stainless steel 304, which is corrosion-resistant and meets GMP production requirements;

The material of the feeding hose is PVC, the temperature range: -10 ℃ ~ 90 ℃;

Conveyor belt material is nylon POM material, good wear resistance.

Parameter

Model: VK-LFM01

Sealing speed: 30-60 bottles/min(customized)

Accuracy: ±1%

Filling type: Piston type

Power: 3KW 220V/380V

Control: Simen PLC Touch screen

Quantity of filing heads: 4/6/8/10/12(customized)

Filling range: 250ML-2500ML

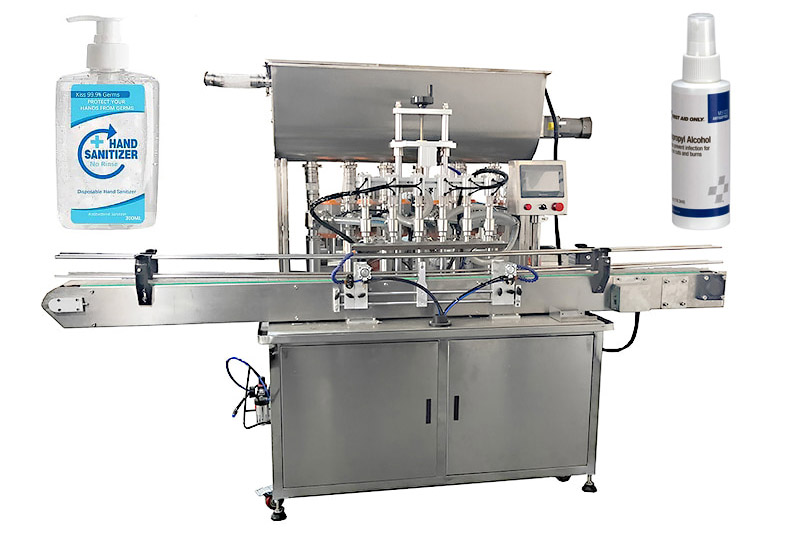

An automatic disinfectant/hand sanitizer/alcohol liquid filling machine is a highly efficient and versatile packaging system designed for filling various types of liquid products into different containers. This type of machine is specifically designed for the production of disinfectant, hand sanitizer, and alcohol-based liquid products.

The machine is equipped with advanced features that make it efficient and easy to use. The system is designed to fill containers with liquid products automatically, with a high level of accuracy and consistency. The machine is also equipped with a computer-controlled system that ensures precise filling volumes and reduces the chances of product wastage.

One of the major advantages of this type of machine is its high efficiency. The automatic disinfectant/hand sanitizer/alcohol liquid filling machine can fill up to 50 containers per minute, resulting in increased production output and reduced labor costs. Additionally, the system is designed to be easy to clean and maintain, which helps to reduce downtime and increase productivity.

The machine is also designed to be flexible. It can be used to fill different types of containers, such as bottles, jars, and tubes, with various types of liquid products of varying viscosities. The system is also adjustable, which means that it can be set to fill different amounts of product, depending on the customer's requirements.

The machine is also designed with safety features that help to ensure the safety of the operators and the system itself. These features include emergency stop buttons, safety sensors, and protective covers that prevent accidents and injuries.

In conclusion, an automatic disinfectant/hand sanitizer/alcohol liquid filling machine is an essential tool for high-volume production facilities that deal with liquid products. The system is efficient, reliable, and easy to use, with advanced features that ensure consistent product quality and safety. It is a valuable investment for any production facility that seeks to increase production output, reduce labor costs, and enhance the overall efficiency of their operations.