Description

Application:

Suitable for packing loose, non sticky powder material in the medicine, food, daily chemical and other industry, and automatic packing into sachets with measuring requirement. Such as coffee powder, milk powder, soymilk powder, starch, drug, pulveres, and so on..

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

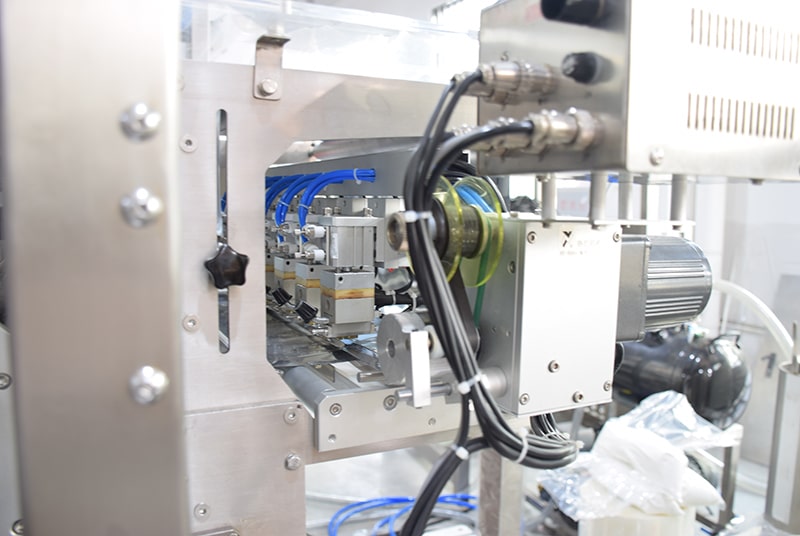

Advanced performance, high power, low noise, compact structure, operate steadily, easy to maintain, and has a long life span. Film sending mechanism can rotate with 90°in level, and add with film contacting mechanism, which make film change and maintain easier.Adopt five shaft servo motor in step driver, man-machine interface touch adjustment, controlled by PLC, it is precise in automatic in step positioning.

A high degree of automation, machine can finish packing at one time from longitudinal sealing, longitudinal cutting, transverse sealing, filling, embossing, notch cutting, cutting dotted line cutting, and transverse cutting to outputting finished sachets.

High precision whole rolling type heat sealing rollers are adopted as sealing mould, four side sealing, and multi-lane sachet form. With high packing speed, smooth bag shape, delicate and beautiful, packing and high efficiency.

Easy and fast to adjust, it can step-less adjust pouch length without changing the mould. And can adjust the functions as longitudinal sealing, transverse sealing, filling, embossing, Dotted line cutting, and transverse cutting through man-machine interface.

Accurate in measurement. According to different granule material, specially designed of cylinder pushing vibrating type or flat shape push pull type adjustable measuring mechanism. Vibrating type matches with triangle adjustable measuring cup feeding mechanism, push pull type designed with plate inside measuring cups, both feeding system can be adjusted independently and accurately, each line’s dosage can be adjusted easily and accurately.

Photoelectric tracking system is adopted to ensure correct printing and with automatic counting function.

The machine with film automatic correction and film damping mechanism, to ensure the straightness and tension stability of film, and make the pouch more smooth and beautiful.

Adaptability of the package film, the sealing temperature of machine is with automatic control, and has high control accuracy(±1℃). Suitable for most complex film packing film: such as PET/AL/PE, PET/PE, NY/ALPE, NY/PE and so on.

Extra functions set up, for example, sachet cutting can choose dotted line knife or flat cutting knife, abnormal shape knife etc, and can choose different kinds of alarm requirement.

Parameter

| Model | VK480F | VK720F | GH960F |

| Track Number | 4~6 Track | 4~10 Track | 4~12 Track |

| Filling Method | Auger Filling by servo motor | ||

| Capacity | Max.40 cycle/min | ||

| Sachet Size | L:45--120mm; W:50-60mm | L:45--120mm; W:50-90mm | L:45--120mm; W:50-120mm |

| Film Width & Thickness | Max.480mm;0.07-0.1mm | Max.720mm;0.07-0.1mm | Max.960mm;0.07-0.1mm |

| Sealing Type | 4 sides sealing | 4 sides sealing | 4 sides sealing |

| Cutting Type | 1. Straight Cutting; 2. Zig Zag Cutting; 3. Continuous Cutting | ||

| Air & Power | 0.8 mpa 0.8m³/min; 2.8kw | 0.8 mpa 0.8m³/min; 4.1kw | 0.8 mpa 0.8m³/min; 5.5kw |

| DIM & WT | 950*1470*1750mm; 300kg | 1153*1654*1750mm; 400kg | 1415*1686*2130mm; 500kg |

Multi line side sealing bag powder packing machines are essential equipment in modern production facilities that deal with powders. These machines are designed to efficiently pack different types of powders into multi-line side-sealed bags, which helps to ensure that products are well-packaged and safe for transportation and storage.

The process of packing powders is not an easy one, and it requires specialized equipment to achieve the best results. A multi-line side sealing bag powder packing machine is a perfect solution for this process. This machine is designed to pack powders in bags of different sizes, shapes, and designs. The machine comes with multiple filling heads, which allow for high-speed filling of the powder into the bags.

Multi-line side sealing bag powder packing machines come with advanced features that make them easy to operate and maintain. These machines are automated, which means that they can be controlled using a computerized control system. The system ensures that the machine operates smoothly and accurately, resulting in consistent product quality.

The machines are also designed with high-quality components, which are durable and require minimal maintenance. The sealing components are made of high-quality materials that can withstand high temperatures and pressure, ensuring that the bags are sealed tightly and securely.

The machines are also equipped with safety features, which help to ensure the safety of the operators and the machine itself. These features include emergency stop buttons, safety sensors, and protective covers that prevent accidents and injuries.

One of the major advantages of multi-line side sealing bag powder packing machines is their high efficiency. These machines are designed to pack powders at high speeds, which increases production output and reduces labor costs. Additionally, the machines are designed to be easy to clean and maintain, which helps to reduce downtime and increase productivity.

In conclusion, multi-line side sealing bag powder packing machines are essential equipment for modern production facilities that deal with powders. These machines are efficient, reliable, and easy to operate and maintain. They come with advanced features that ensure consistent product quality and safety, making them a valuable investment for any production facility.