Description

Application:

All kinds of grains and solids material, like popcorn, candy, nuts, raisins, peanuts, melon seeds, nuts, nutlet, chocolate, preserved fruit, potato chips, biscuits, confect, camphorball, currant, almond, potato crisps, pet food, dilatant food etc can be weighed by the ration. It is also suitable for weighing small hardware and plastic component.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. wide applications: various state and nature of solid(granule);

2. A wide range of pouches: all kinds of pre-made pouches;

3. Easy to operate: PLC controller, HMI system makes easy operation;

4. Easy to adjust: change different pouches within 10 minutes;

5. High automation: unmanned in weighing and packing process, machine alarm automatically when failure;

6. Perfect prevention system: when the bag is not opened or not opened completely, it will be non-filling and non-sealing, so the bags can be reused and the product is not wasted thus save the production cost;

7. The product contact parts are adopted SUS304 to ensure sanitation and safety, meet the GMP standard;

8. Imported engineer plastic bearings, no need to oil, no contamination;

9. Vacuum generator: low consumption, high efficiency, cleaness, and long useful life;

10. Pre-made bag packing: perfect sealing quality, upgrade the finished product.

Parameter

| Model | VK-8200/VK-8250 |

| Packing material | 3-side, four edge-sealing bag, self-reliance bag, handbag, spout bags, zipper bag, compound bag, etc |

| size | W:70-200/100-250 |

| Filling range | 10-1000g/20-2500g |

| Packing speed | 40-60bag/min(speed is determined by the product filling quantity) |

| Average precision | ≤ ±1% |

| Total power | 2.5KW |

| Dimensions | 1900mm X 1570mm X 1700mm(L*W*H) |

| Work flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

| Main standard parts | 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

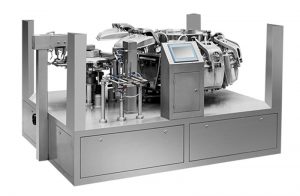

An automatic popcorn premade pouch packing machine is a specialized machine designed to pack popcorn into pre-made pouches automatically. This type of machine is specifically designed for high-volume production facilities that require reliable and consistent packing of popcorn products.

The machine is equipped with advanced features that make it efficient and easy to use. It can automatically open pre-made pouches, fill them with popcorn, and seal them to ensure product freshness. The system is designed to work with a variety of pre-made pouches, including stand-up pouches, flat pouches, and zip-lock pouches.

One of the major advantages of this type of machine is its high efficiency. The automatic popcorn premade pouch packing machine can pack up to 50 pouches per minute, resulting in increased production output and reduced labor costs. Additionally, the system is designed to be easy to clean and maintain, which helps to reduce downtime and increase productivity.

The machine is also designed to be flexible. It can be used to pack different types of popcorn products, with varying volumes, into different pre-made pouches. The system is also adjustable, which means that it can be set to pack different amounts of product, depending on the customer's requirements.

The machine is also designed with safety features that help to ensure the safety of the operators and the system itself. These features include emergency stop buttons, safety sensors, and protective covers that prevent accidents and injuries.

In conclusion, an automatic popcorn premade pouch packing machine is an essential tool for high-volume production facilities that deal with popcorn products. The system is efficient, reliable, and easy to use, with advanced features that ensure consistent product quality and safety. It is a valuable investment for any production facility that seeks to increase production output, reduce labor costs, and enhance the overall efficiency of their operations.