Description

Application:

Suitable for many kinds of loose granule products, such as sugar, salt, small grains, seeds, spice, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

Multi lanes machine can produce multi lanes bags at same time.

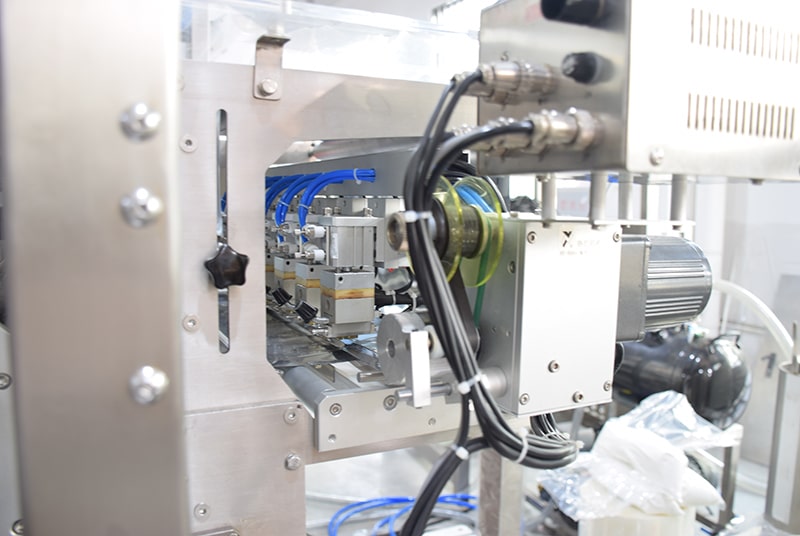

Machine main function: automatic split film at right position, liquid measuring and filling, multi lanes bag form fill seal, cutting, sensor tracking, counting capacity.

Other function: Emergency stop, set capacity to auto stop machine, count capacity and Zero the count, ready bag output, manual test machine each step etc.

Stainless steel contact part and the machine outer shell, high feature for liquid running environment.

High precision photocell sensor for auto tracking the eye mark printing on the film roll, so cut each bag at precisely position.

PLC controller, high function and control the whole machine’s work steps.

Parameter

| Model | VK-280BF | VK-560BF |

| Lane number | 4-6 Line | 8-12 Line |

| Filling Method | 1.Volumetric cup; 2. Weigher | |

| Capacity | Max.35 cycle/ min | |

| Sachat Size | L:50-180mm; W:17-30mm | L:50-180mm; W:17-30mm |

| Film weidth & Thickness | Max.280mm, 0.07-0.10mm | Max.560mm, 0.07-0.10mm |

| Sealing type | Back sealing/Stick bag | Back sealing/Stick bag |

| Cutting type | 1.Straight cutting; 2.Zig zag cutting; 3.Round cutting; 4.Irregular | |

| Air & Powder | 0.8Mpa 0.8m3/min; 3.5kw | 0.8Mpa 0.8m3/min; 5.5kw |

| Dimension & weight | 1385*918*2005mm;350kg | 1685*1300*2005mm;550kg |

The Multi-Line Back Sealing Granule Packing Machine is a high-performance packaging equipment designed for efficiently and effectively packaging granular products, such as coffee, tea, spices, and other food ingredients. It is capable of producing multiple bags simultaneously, making it a versatile and cost-effective solution for manufacturers with high-volume production requirements.

The machine's back sealing mechanism ensures that the product is securely packaged, preventing contamination and preserving freshness. The multi-line design allows for increased output, with up to four lines of production, and the ability to adjust the bag length and width to accommodate different packaging needs.

The Multi-Line Back Sealing Granule Packing Machine features a user-friendly interface that enables operators to easily set and adjust various parameters such as bag length, bag width, and filling volume. The touch screen display provides real-time updates on the production process, and the machine can be easily integrated into existing production lines.

This machine is designed to handle a variety of granular products, and its high-precision filling system ensures accurate and consistent filling. Additionally, the machine's sensors detect any abnormalities in the packaging process and automatically stop the machine to prevent damage or waste.

The Multi-Line Back Sealing Granule Packing Machine is built with high-quality materials and advanced technology, ensuring durability, reliability, and minimal downtime. The machine's modular design allows for easy maintenance and replacement of parts, reducing downtime and increasing the longevity of the equipment.

In summary, the Multi-Line Back Sealing Granule Packing Machine is a versatile and efficient packaging solution for manufacturers with high-volume production requirements. Its multi-line design, user-friendly interface, and high-precision filling system make it a cost-effective option for packaging granular products, while its durability and reliability ensure consistent performance and minimal downtime.