Description

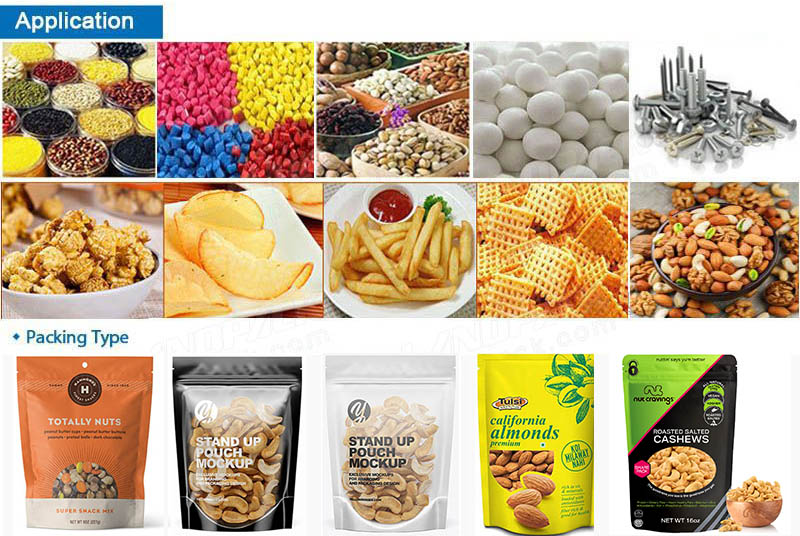

Application:

Suitable for various granlue material in premade pouch style, such as beans, nuts, dry fruits, candy, cereal, chocolate, biscuit, peanut, capsule, seeds, chemicals, sugar, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

Touch Screen: China Kinco 7 inches corlor touch screen;

Languages: Chinese, English, Spanish, Dutch, Italian, Korean (At most three languages);

PLC: Japan Panasonic;

Cylinder: Taiwai Airtac (Can be upgraded to Japan SMC);

Vacuum Generator: China Airbest (Can be upgraded to Vacuum Pump);

Vacuum Component: Japan SMC;

Modular Control System For Vacuum Pressure: Japan SMC;

Modular Control System For Temperature: China YUDIAN;

Electrical Component: Schneider / Omron;

Safety Key Interlock Switch;

The main structure of the machine is SUS304 (The thickness of the rack is 3.0mm), and the material of the part is aluminum;

The part (Hopper) in contact with the material is SUS304 (Can be upgraded to SUS316L).

Parameter

| Model | 300AX/430A |

| Bag Material | Multilayer Composite Premade Bag(e.g.: PET/PE) |

| Bag Type | 3 Side Seal Bag, Stand-up Bag |

| Speed | 0~15bags/min |

| Sealing Type | Straight grain, pitch is 1mm (Optional reticulate) |

| Sealing Width | 10mm (5--20mm can be customized) |

| Voltage | 220V, Single-phase, 50/60HZ, 1.2KW |

| Air Pressure | 0.65Mpa |

| Air Consumption | 0.3m³/min (Standard machine, no additional function) |

| Body Dimension | 1770*600*1260mm |

| Packing Dimension | 1860*710*1650mm (Export non-fumigation wooden case) |

The Mini Doypack Packing Machine and Smart Four Head Linear Scale is an ideal solution for businesses looking to maximize efficiency. This powerful combination of equipment offers a range of features that allow businesses to quickly and accurately package products in a variety of sizes. The mini doypack machine offers fast, reliable sealing and filling capabilities, while the four head linear scale provides precise weight measurement for each package. Together, these two pieces of equipment provide an efficient and cost-effective way to package products with minimal effort.

Maximizing Efficiency with Mini Doypack Packing Machine and Smart Four Head Linear Scale

The Mini Doypack Packing Machine and Smart Four Head Linear Scale are designed to maximize efficiency in the food packaging industry. This advanced technology is capable of packing a wide variety of products, from liquids to solids, with accuracy and speed. The machine features a robust stainless steel construction, ensuring long-term durability and reliability. It is also equipped with an easy-to-use touchscreen interface for convenient operation.

The Smart Four Head Linear Scale provides precise weight measurements for each package. This ensures that each package contains the correct amount of product and helps reduce waste. The scale also features a built-in calibration system for accuracy and reliability. Additionally, it has a built-in printer for easy labeling and tracking of products.

The Mini Doypack Packing Machine and Smart Four Head Linear Scale are designed to maximize efficiency in the food packaging industry. This advanced technology offers superior performance, accuracy, and speed while reducing waste and labor costs. With its robust construction, easy-to-use touchscreen interface, precise weight measurements, and built-in printer, this system is an ideal solution for any food packaging business looking to increase efficiency while maintaining quality standards.

Utilizing Advanced Technology to Enhance Productivity in Mini Doypack Packing

Utilizing advanced technology to enhance productivity in mini doypack packing is a key component of efficient operations. Automated systems are capable of providing a high level of accuracy and speed, while reducing labor costs and increasing production output. Automated mini doypack packing systems can include robotic arms, vision systems, and other components that allow for precise and consistent filling of packages. These systems are designed to minimize the amount of manual labor required for the packing process, resulting in faster production speeds and improved product quality. Additionally, automated mini doypack packing systems can be integrated with existing production lines to further streamline the process. By leveraging advanced technology, companies can maximize their productivity and minimize their costs while producing high-quality products.

Optimizing Output with Automated Packaging Solutions

Automated packaging solutions are designed to optimize output and increase efficiency in the packaging process. These solutions use advanced technology to streamline operations, reduce costs, and improve the quality of products. Automated packaging systems can be used for a variety of applications, including product assembly, labeling, palletizing, shrink wrapping, and more.

The automated packaging process begins with a comprehensive analysis of the customer’s requirements. This includes an assessment of the type of product being packaged, the size and shape of the package, and any special requirements for handling or storage. Based on this information, a custom-designed automated packaging system is created to meet the customer’s needs.

The automated system is designed to maximize efficiency by minimizing manual labor and eliminating errors. It can be programmed to accurately count items and label them with barcodes or RFID tags for easy tracking. The system can also be programmed to assemble packages in specific sizes or shapes according to customer specifications. In addition, automated systems can be programmed to automatically apply shrink wrap or other protective materials as needed.

Automated packaging solutions offer many benefits over traditional manual methods. They provide faster turnaround times while ensuring accuracy and consistency in product quality. Automated systems also reduce labor costs by eliminating manual labor tasks such as counting items or applying labels. Finally, automated systems help reduce waste by ensuring that packages are properly sealed and protected from damage during shipping or storage.

Leveraging Automation to Increase Speed and Accuracy of Mini Doypack Packaging

Leveraging automation in mini doypack packaging can help increase speed and accuracy of the process. Automation solutions can be used to streamline the packaging process, allowing for faster and more accurate packing of mini doypacks. Automated solutions can include robotic arms, conveyor belts, and other advanced technologies that are designed to improve the speed and accuracy of the packaging process. Automation can also help reduce manual labor costs associated with mini doypack packaging, as well as reduce human error that could lead to product defects or mislabeling. Additionally, automation can provide greater control over the packing process, allowing for improved tracking and monitoring of product quality. By leveraging automation in mini doypack packaging, companies can achieve greater efficiency and accuracy while reducing costs associated with manual labor.

Streamlining Processes with Smart Four Head Linear Scale for Mini Doypack Packaging

The Smart Four Head Linear Scale for Mini Doypack Packaging is an efficient and reliable solution for streamlining processes in the food packaging industry. This machine is designed to quickly and accurately weigh and fill small doypack bags with precise amounts of product. It features four linear weighing heads that are capable of accurately weighing up to 10 grams per head, allowing for fast and accurate filling of mini doypack bags. The machine also includes a digital display that allows users to easily monitor the weight of each bag, ensuring accuracy and consistency in the filling process. Additionally, the machine is equipped with a user-friendly interface that makes it easy to operate and adjust settings according to specific needs. This ensures that the process runs smoothly and efficiently, resulting in faster production times and improved product quality.

Conclusion

The Mini Doypack Packing Machine and Smart Four Head Linear Scale offer an efficient and cost-effective solution for businesses looking to maximize their production output. This combination of machines is capable of packing a wide range of products in various sizes quickly and accurately, ensuring maximum efficiency and minimum waste. The intuitive user interface makes it easy to set up and operate, while the robust construction ensures a long service life. With its reliable performance, this system is an ideal choice for businesses looking to maximize their efficiency and profitability.