Description

Application:

Suitable for packing regular objects such as Fruit Vegetable biscuits, pies, bread, fresh fruits & vegetable, instant noodles, drugs, daily appliances, industrial parts, paper boxes, plates, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

For Stable Performance: Dual inverters controller, upgradable PLC system, self-failure diagnosis, double encoder.

For Easy Operation: Touch screen monitor, independant temperature PID controller.

For Adapability: one set of machine can be applicated to different kind of product via optional devices, such as air-filling device, feeding line, date printer, etc.

Parameter

| Model | VK-250X | VK-350X | VK-450X | VK-600X | VK-700X |

| Film Width | Max.250mm | Max.350mm | Max.450mm | Max.600mm | Max.700mm |

| Bag Length | 65-280mm | 65-330mm | 150-450mm | 160-500mm | 180-600mm |

| Bag Width | 30-110mm | 50-160mm | 50-180mm | 100-280mm | 100-330mm |

| Product Height | Max.45mm | Max.65mm | Max.80mm | Max.110mm | Max.110mm |

| Packing Speed | 40-230bag/min | 40-230bag/min | 40-150bag/min | 20-150bag/min | 20-130bag/min |

| Power | 220V 50/60Hz | 220V 50/60Hz | 220v 50/60Hz | 220v 50/60Hz | 220V 50/60Hz |

| 2.4KW | 2.8KW | 2.8KW | 2.8KW | 2.8KW | |

| Machine Size(L*W*H)mm | 3920*670*1320 | 4020*720*1320 | 4150*820*1450 | 4300*920*1460 | 4380*980*1480 |

| Machine Weight | About 500kg | About 550kg | About 650kg | About 680kg | About 720kg |

| Optional Devices: | 1.Lateral feed device, 2.Straight feed device, 3.Belt material conveyor. 4.End sealing auxiliary conveyor, 5.Auxiliary material feeding device, 6.Materia cut prevent device 7.Perforating device, 8.Angle folding device, 9.Date Printer, 10.Labelling machine | ||||

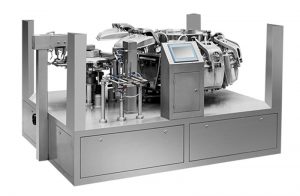

A Fruit/Vegetable Reciprocating Flow Pack Machine (HFFS) with Three Servo is a high-performance packaging solution designed to meet the unique requirements of fruits and vegetables. This machine uses a reciprocating motion to pack a variety of products into flow packs, ensuring that they are stored and preserved at optimal conditions.

One of the key advantages of this machine is its three servo motors, which enable precise and efficient packaging. The servo motors control the feeding, cutting, and sealing processes, allowing the machine to adjust to different product sizes and shapes, and ensure that they are packed consistently and accurately. This results in high-quality packaging that meets the standards of both the manufacturer and the end-user.

Furthermore, the Fruit/Vegetable Reciprocating Flow Pack Machine (HFFS) with Three Servo is highly versatile and can accommodate a variety of product types, including fresh produce, frozen fruits and vegetables, and dried fruits and nuts. The machine can also be configured to handle different packaging sizes and materials, such as laminated films, PE films, and aluminum foils, ensuring that it meets the unique needs of each business.

In addition, this machine is equipped with advanced automation features, such as a touch screen interface and a programmable logic controller (PLC), which allows for easy operation and maintenance. The touch screen interface provides the operator with real-time information on the machine's performance, while the PLC ensures that the machine runs at optimal conditions, minimizing the risk of errors and downtime.

Moreover, the Fruit/Vegetable Reciprocating Flow Pack Machine (HFFS) with Three Servo is designed with hygiene and safety in mind. The machine is constructed using food-grade materials and features a stainless-steel exterior, which is easy to clean and maintain. Additionally, the machine is equipped with safety sensors and guards, which protect the operator and prevent accidents during operation.

In conclusion, the Fruit/Vegetable Reciprocating Flow Pack Machine (HFFS) with Three Servo is a high-performance packaging solution that offers a range of benefits to businesses in the fruit and vegetable industry. With its precise and efficient packaging, versatility, advanced automation features, and focus on hygiene and safety, this machine can significantly improve productivity, reduce labor costs, and enhance the quality of the packed product.