Description

Application:

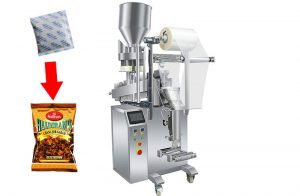

This machine is suitable for four-sides sealing bag packing, such as various surgical mask, kn94 mask, medical masks, disposable masks, and other articles in paper and plastic bags.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1.The four-side sealing mask packaging machine color touch screen operation interface is simple to operate. It adopts a scientific 4-axis servo drive system and a PLC programmable controller intelligently controls the operation of the whole machine. It has the advantages of precise film feeding, stable material transfer, and precise bag cutting.

2. Innovative design: independent guide pillar mold base, mobile synchronous heat sealing system, the temperature of the sealing surface is more uniform and stable, the sealing edge is tight, and it is durable. Packaging materials of different thicknesses and materials are more adaptable.

Parameter

| Specification model | VK-FD4D |

| Processing capacity | 40-60 bags/min |

| Applicable raw materials | Single mask |

| Bag size | Length 220 mm×Width 140mm |

| Roll film size | Φ≤350 mm, width 200-600 mm, inner diameter of paper core 76.2mm |

| Roll film material | Paper aluminum plastic, pure aluminum, aluminized, coated paper, composite transparent film, etc. |

| Total power | 220v 50Hz motor 2.2KW heating 3.3KW |

| Air consumption | ≥30m3/h (self-provided), pressure: 0.6-0.8Mpa |

Automating your surgical mask packaging with a four-sides sealing bag packing machine is an efficient and cost-effective way to increase productivity and reduce labor costs. This type of machine is designed to quickly package medical masks into bags that are sealed on all four sides, ensuring the product is securely contained. The machine's size makes it suitable for use in a variety of settings, from small clinics to large manufacturing facilities. It features adjustable speed control and automatic detection systems for added safety and accuracy, making it easy to produce consistent results with minimal effort. With its high-quality construction and reliable performance, this four-sides sealing bag packing machine is an ideal solution for automating your surgical mask packaging process.

Benefits of Automating Surgical Mask Packaging with a Four-Sides Sealing Bag Packing Machine

A four-sides sealing bag packing machine is an automated system that provides a reliable and efficient solution for packaging surgical masks. This machine utilizes advanced technology to ensure that the masks are sealed properly, preventing contamination and preserving the integrity of the product. The machine also features a user-friendly interface, allowing for easy operation and minimal training requirements. Additionally, this system offers a number of benefits including increased productivity, improved safety standards, reduced labor costs, and improved quality control. With its ability to quickly package large quantities of surgical masks in a safe and secure manner, this automated system is an ideal choice for any medical facility looking to streamline their packaging process.

Overview of the Four-Sides Sealing Bag Packing Machine for Surgical Mask Packaging

The Four-Sides Sealing Bag Packing Machine for Surgical Mask Packaging is a high-performance machine designed to meet the needs of medical and healthcare industries. This machine is capable of producing four-sided sealed bags with precise dimensions, ensuring that surgical masks are safely and securely packaged. It features an advanced PLC control system, a servo motor drive system, and a touch screen display for easy operation. The machine also has an automatic detection system to detect any defects in the packaging process. With its high speed and accuracy, this packing machine can provide reliable packaging solutions for medical and healthcare applications.

Considerations for Choosing the Right Four-Sides Sealing Bag Packing Machine for Your Surgical Mask Packaging Needs

When it comes to selecting the right four-sides sealing bag packing machine for your surgical mask packaging needs, there are several important considerations to keep in mind. First and foremost, you should consider the type of materials that the machine can handle. Different machines are designed to work with different types of materials, so it is important to make sure that your chosen machine is compatible with the type of material you plan on using for your masks.

Second, you should consider the size and capacity of the machine. Depending on how many masks you plan on packaging at once, you may need a larger or smaller machine with higher or lower capacity. It is also important to consider whether or not a particular model has adjustable settings so that it can be adjusted for different sized packages as needed.

Thirdly, you should take into account any additional features that may be available on a particular model such as automated loading systems and safety features like emergency stop buttons. Additionally, some models come equipped with additional functions such as coding systems which allow for more accurate tracking and labeling of packages during production runs.

Finally, it is important to research various brands and models before making a final decision in order to ensure that you are getting the best quality product possible at an affordable price point. By taking all these factors into consideration when choosing a four-sides sealing bag packing machine for your surgical mask packaging needs, you can rest assured knowing that your chosen solution will meet all of your requirements while providing optimal performance throughout its lifetime.

Installation and Maintenance Requirements for a Four-Sides Sealing Bag Packing Machine

The four-sides sealing bag packing machine is a versatile and efficient piece of equipment for packaging a variety of products. It is designed to create tight, secure seals on all four sides of the bag, ensuring the contents remain secure and protected during transport. To ensure optimal performance and longevity, proper installation and maintenance are essential.

Installation requires careful attention to detail to ensure the machine is properly set up for operation. This includes mounting the machine securely to a stable surface, connecting power cables correctly, aligning parts correctly, calibrating settings accurately according to product specifications, testing safety features regularly and ensuring that all components are in good working order before use.

Maintenance requirements include regular cleaning of parts with an approved cleaner or lubricant as needed; inspecting belts and other moving parts for signs of wear or damage; checking electrical connections; checking settings regularly against product specifications; replacing worn or damaged components as needed; lubricating moving parts as necessary; storing unused components in a clean environment away from dust and dirt; following manufacturer’s instructions when making adjustments or repairs; keeping records of maintenance activities performed on the machine; adhering to safety guidelines at all times while operating the machine.

Troubleshooting Common Issues with a Four-Sides Sealing Packing Machine for Surgical Mask Packaging

Troubleshooting common issues with a four-sides sealing packing machine for surgical mask packaging can be a challenging task. The most common problems encountered include improper sealing, insufficient air pressure, and incorrect material feeding. To troubleshoot these issues, it is important to inspect the machine’s components for wear and tear, as well as ensure that all settings are properly adjusted. Additionally, checking the quality of the materials used in the packaging process is essential to ensure proper functioning of the machine. By following these steps and troubleshooting any issues that arise, users can ensure that their four-sides sealing packing machine runs smoothly and efficiently for optimal performance.

Conclusion

The Four-Sides Sealing Bag Packing Machine is an ideal solution for automating the surgical mask packaging process. This machine provides a reliable and efficient way to package masks in a variety of sizes quickly and accurately. The four-sides sealing technology ensures that the packages are airtight, protecting the masks from moisture and dust while providing an attractive presentation. With its high-speed operation, this machine can significantly reduce labor costs while increasing productivity. Furthermore, its easy to use interface makes it simple to operate with minimal training required. Automating your surgical mask packaging with a Four-Sides Sealing Bag Packing Machine is an effective way to improve efficiency and reduce costs in your production line.