An automatic cannabis flower bottles weighing filling line is a specialized equipment used to package cannabis flower into bottles. This machine is designed to weigh and fill bottles with the correct amount of cannabis flower automatically. This automated process eliminates the need for manual labor, making the packaging process faster, more efficient, and more accurate.

The automatic cannabis flower bottles weighing filling line typically consists of several components, including a conveyor belt, a weighing machine, a filling machine, and a capping machine. The conveyor belt transports the empty bottles to the weighing machine, where the weight of the bottle is measured. This information is then used to determine the amount of cannabis flower that needs to be added to the bottle.

The filling machine dispenses the cannabis flower into the bottle based on the weight measured by the weighing machine. This process is highly accurate and ensures that each bottle contains the correct amount of cannabis flower. Once the bottle is filled, it moves on to the capping machine, which seals the bottle with a cap or lid.

One of the main advantages of using an automatic cannabis flower bottles weighing filling line is that it can package cannabis flower at a high speed, reducing production time and increasing output. The accuracy of the weighing and filling process also ensures that each bottle contains the correct amount of cannabis flower, which is important for quality control and compliance with regulations.

Another advantage of using an automatic cannabis flower bottles weighing filling line is that it reduces the risk of contamination. Manual packaging can introduce contaminants into the product, which can compromise its quality and safety. With an automated system, the risk of contamination is significantly reduced, making the product safer and more consistent.

Overall, an automatic cannabis flower bottles weighing filling line is a valuable piece of equipment for cannabis producers. It can improve efficiency, accuracy, and safety in the packaging process, ultimately leading to higher quality products and increased customer satisfaction.

Description

Application:

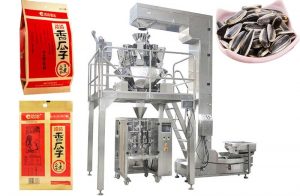

Full automatic granule bottles weighing filling capping and labeling lines, Scope of application: granular and solid materials such as marijuana, cannabis, beans, nuts, dry fruits, candy, cereal, chocolate, biscuit, peanut, capsule, seeds, chemicals, sugar, etc.

Filling Containers: bottles; plastic cans; glass cans; tinplate cans; cartons, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

1. This production line adopts automation technology, imported PLC, imported inspection light eye, frequency converter and other electrical appliances, pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability, good stability, etc., and is well received by users;

2. This line uses automatic bottle feeding, linear scale filling machine, four-wheel capping machine, wafer positioning round bottle labeling machine, and collection platform to form a fully automated production line;

3. The machine frame of the whole line is made of SUS304 material, with a unique and beautiful appearance;

4. The production line has stable operation, low noise, convenient maintenance, and fully meets the requirements of GMP certification, and is widely used in medicine, food and other industries;

5. Imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

6. This kind of production line is relatively advanced, and can be improved according to the different requirements of customers, and can be made into equipment that fully meets the needs of customers.

Parameter

Brief Introduction:

This automatic filling production line is suitable for filling and filling various granular and solid materials. It is called linear metering method with high precision. It forms an automated production line with capping machine, aluminum foil sealing machine, and labeling machine. The production line has stable operation, low noise, simple operation, wide adaptability and meets GMP certification requirements.

| Model | VKZX-SC-10 |

| Filling Speed | 10-20 Bottles / min |

| Bottle diameter | Φ30mm-Φ135mm(customizable) |

| Bottle height | 40mm-200mm(customizable) |

| Control system | PLC |

| Total lines power | 6.8KW |

| Power supply | 220V、50Hz |

| Airconsumption | 0.6m³/min |

| Equipment material | 304 stainless steel |

Description Of Main Packaging Process:

①Bottle Unscrambler → ② Automatic Granule Weighting And Filling Machine → ③Automatic Capping Machine → ④Automatic Electromagnetic Induction Aluminum Foll Sealing Machine → ⑤Automatic Labeling Machine → ⑥ Operation Desk