Description

Application:

Packaging various kinds of regular objects like Candy, chocolate, chewing gum and suit for square, spherical, disc, cylindrical, kinked, oval and all kinds of special-shaped candies and solid blocks.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

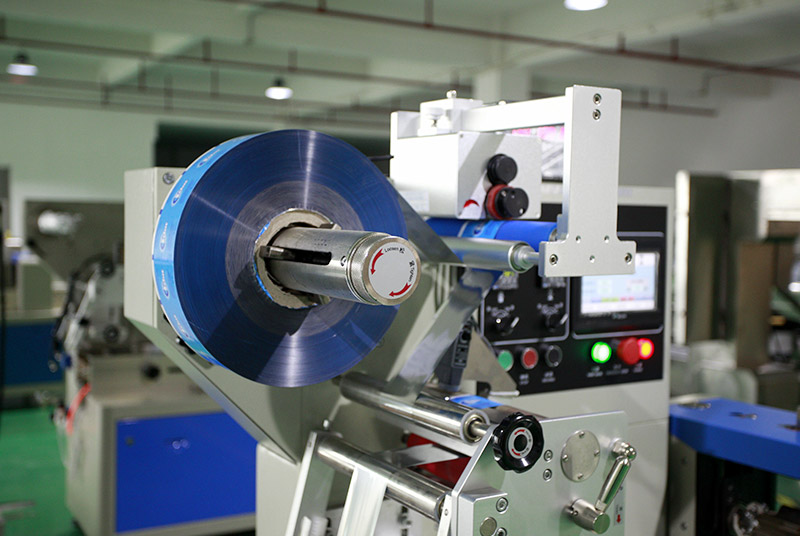

Stable and operating smoothly,

Philips or Panasonic electrical control system, LCD display, parameter set is simple,

Superscript highly sensitive photoelectric eye tracking the exact location so that more precise closure,

Temperature controlled by an independent PID better packaging matericals for various films,

Large rotating disk with automatic, air package rates the best results.

Parameter

| Type: | 250C |

| Packing speed: | up to 800bag/min |

| Specifications: | rectangular square,round,oval,profiled |

| Bag length: | 45-90mm |

| Total power: | 3.5KW |

| Power: | 220V/380V |

| Dimensions: | 3000X1350X1430 |

| Machine weight : | 980kg |

An automatic candy flow wrap packing machine is a specialized equipment designed to package candy products in a fast, accurate, and efficient manner. It is equipped with a flow wrapper that uses advanced technology to wrap the candy product in a sealed film, ensuring freshness and quality during transportation and storage. The machine can pack a range of candy types and sizes, from small hard candies to larger chewy candies. Here are some frequently asked questions about this type of packaging machine:

What is an automatic candy flow wrap packing machine?

A: An automatic candy flow wrap packing machine is a machine that is specifically designed to wrap and pack candy products using a flow wrapper. The machine is equipped with a conveyor belt that transports the candy product to the flow wrapper, which then wraps the product in a sealed film.

How does the machine work?

A: The machine works by first feeding candy products into a hopper, where they are then transported to the flow wrapper using a conveyor belt. The flow wrapper then wraps the candy product in a sealed film, ensuring freshness and quality during transportation and storage. The wrapped candy products are then transported to an output conveyor belt, ready for distribution.

What are the advantages of using an automatic candy flow wrap packing machine?

A: There are several advantages of using an automatic candy flow wrap packing machine, including:

High speed: The machine can pack large quantities of candy products in a short amount of time, increasing production efficiency.

Consistent quality: The machine ensures that each candy product is wrapped in a sealed film, ensuring consistent quality and freshness for the end-user.

Flexibility: The machine can wrap and pack a range of candy types and sizes, from small hard candies to larger chewy candies.

Reduced labor costs: The machine eliminates the need for manual labor, reducing labor costs and increasing efficiency.

What types of candy can the machine wrap and pack?

A: The machine can wrap and pack a range of candy types and sizes, including hard candies, chewy candies, and even chocolate products. The size and type of candy can be customized based on the needs of the business.

Is the machine suitable for small businesses?

A: Yes, there are automatic candy flow wrap packing machines available that are suitable for small businesses. These machines are smaller in size and capacity but still offer the same level of precision and efficiency as larger machines.

In conclusion, an automatic candy flow wrap packing machine is a valuable investment for businesses in the candy industry that require accurate and efficient packaging processes for their products. The machine offers several advantages over manual labor, including high speed, consistent quality, flexibility, and reduced labor costs. With the ability to wrap and pack a range of candy types and sizes, businesses of all sizes can benefit from using this type of packaging machine.